Contact us: +91- 788 2974180,81

+91- 75662 92110

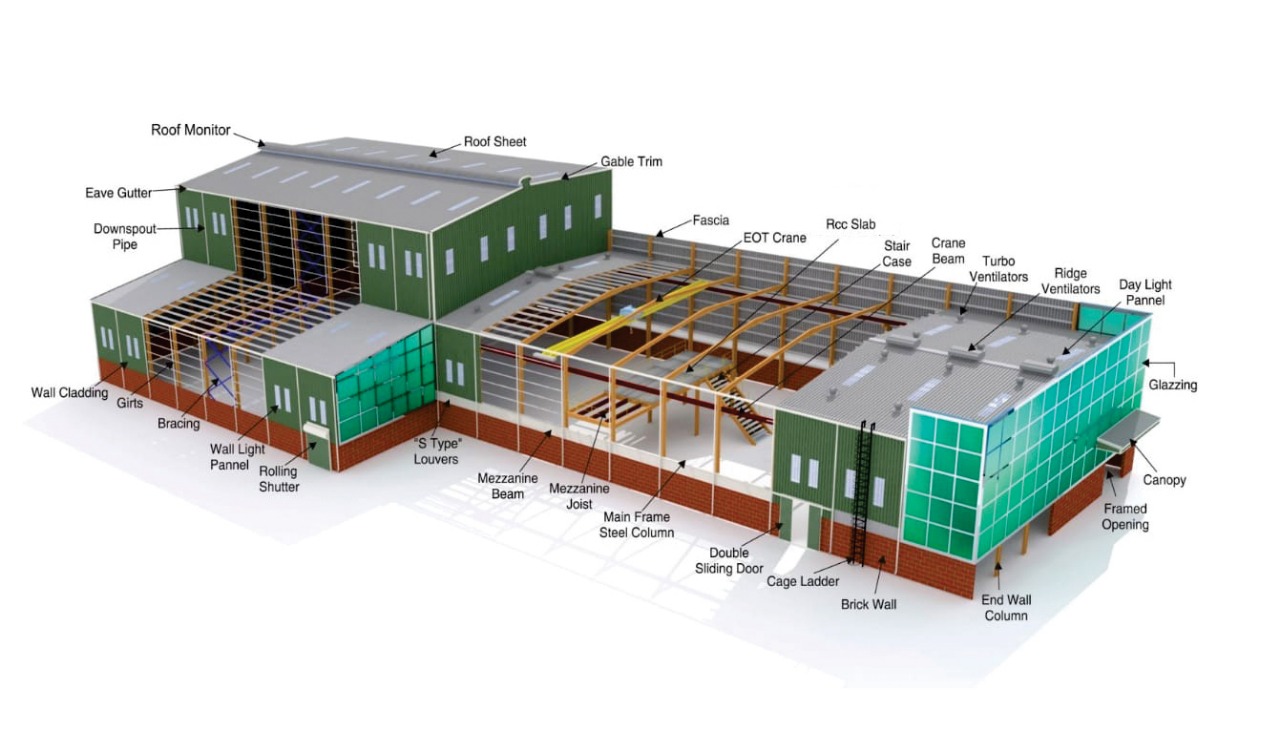

Pre-engineered Buildings

A Pre-Engineered building (PEB) is designed to be fabricated using best suited raw materials and manufacturing methods that can efficiently satisfy a wide range of functional, structural and aesthetic design requirements.

Historically, the primary framing structure of a Pre-fabricated Building is an assembly of I-shaped members, often referred as I-beams. In Pre-engineered Buildings, the I beams used are usually formed by welding together steel plates to form the I section. The beams are then field-assembled (e.g. bolted connections) to form the entire frame of the pre-engineered building.

An efficiently designed Pre-engineered Building can be lighter than the conventional steel buildings by up to 30%. Lighter weight equates to less steel and a potential price savings in structural framework. PEBs are resistant to moisture, adverse weather conditions, earthquakes, termites and fire. They provide life-long durability, safety and very low-cost maintenance.

Key Benefits of PEBs are:

- Reduced Construction Time

- Flexibility of Expansion

- Large Clear Spans

- Low Maintenance

- Energy-efficient Roofing & Wall

- Variety of Options to Suit the Internal Temperature Requirement from Ambient to Refrigeration

Associated Services

- Civil Foundation & Super-Structure Design & Execution

- Electrical Design & Execution

- Solar Panel Design & Installation

Amazing facts about PEB:

- Steel is recyclable material where as conventional concrete is still struggling to achieve recycling.

- Steel is one of the leading choices when it comes to creating strong structures that can withstand adverse meteorological conditions.